The Q8Oils laboratories are equipped with an extensive range of analytical tools to determine performance and characteristics of newly formulated oils. Among these are high pressure differential scanning calorimeters (HPDSC), kinematic viscosity analysers (KV), rotating pressure vessel oxidation test (RPVOT), total acid number (TAN) and total base number (TBN) analysers, Gas chromatography–mass spectrometry (GC-MS), and Infrared spectroscopy (IR).

As separate elements of the formulation are mixed they are tested to ensure that the correct output will be achieved, and in many cases will act as marker points to verify the health of the oil during service.

- Viscosity (KV)

An oil’s kinematic viscosity is defined as its resistance to flow and shear due to gravity, and is regarded as one of an oil’s most important physical properties. Used as a marker to analyse working oil, an increase in KV can indicate oil oxidation, the addition of improper grade oil, fuel soot build up, dirt and antifreeze contamination. Decreased KV can indicate fuel dilution, addition of an improper grade oil or viscosity modifiers. - Total Base Number (TBN)

TBN is an indication of the oil’s reserve to counteract acids. The higher the TBN, the greater will be the levels of protection against acids. - Total Acid Number (TAN)

TAN is defined as the amount of acid and acid-like material in the oil. Oxidation and nitration products make up the majority of this material. TAN analysis is used to establish the optimum oil drain interval. - Oxidation/Nitration

Testing to ASTM D6186 standard using a HPDSC enables the laboratory to establish an oxidation induction time (OIT). The longer the OIT, the longer the oil will resist deterioration.

An Alternative method to determine oxidation stability is to mix oil, oxygen and catalysts in a pressure vessel (rotating bomb), heated to 150 °C. Pressure reduction in the container determines the ageing/oxidation process.

Oxidation, nitration, and sulfation products shown on the infrared spectroscope produce different peak levels, and the results obtained from the new grade will be used to monitor in-service performance.

Q8 Mahler Series – no compromise on performance

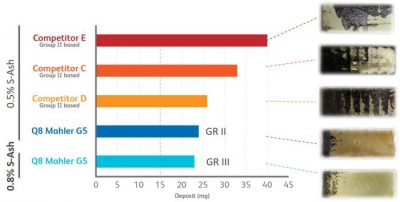

Deposit control – Panel Coker

The deposit control of the Q8 Mahler GR series is excellent

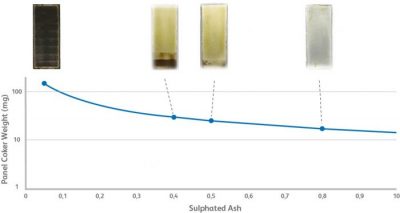

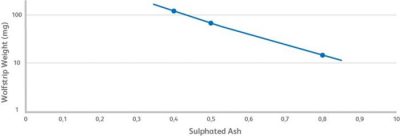

Higher ash products for Steel Piston engines – Panel coker study

Higher ash products for Steel Piston engines – Panel coker study

Test method: the oil is circulated over a panel at 290°C for 2×6 hours. After the test the panel is weighed and rated.

| Q8 Mahler G4 | Q8 Mahler G5 | Q8 Mahler G8 | |

| Deposit (mg) | 123 | 72 | 15 |

| Rating (1…10), higher is better | 8 | 9 | 9 |

Field trials

With the formulation of the new grade completed, it only remains for field trials to be undertaken, and if the results match the expectations, the product can go into production.

Casestudy 1: Vinderup, Denemarken (Q8 Mahler GR5 – Biogas – Stalen zuiger – 20 bar BMEP)

Routine analysis, laboratory testing:

- Engine INNIO Jenbacher

- Model 620 GS-B.L

- Build year 2012

- Gas type Biogas

- Oil Q8 Mahler GR5

Over 4.000 hr drain interval with Q8 Mahler GR5

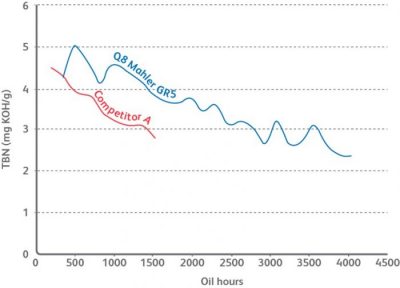

Over 4.000 hr drain interval with Q8 Mahler GR5* – Total base number

*Performance of competitor at equivalent conditions. Same engine, same operating conditions, same gas.

**OEM maintenance schedule: 2.000 hr, OEM approved reference: 1.500 hr

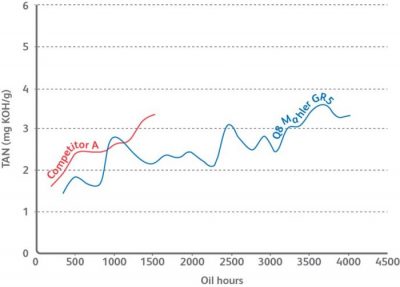

Over 4.000 hr drain interval with Q8 Mahler GR5* – Total acid number

*Performance of competitor at equivalent conditions. Same engine, same operating conditions, same gas.

**OEM maintenance schedule: 2.000 hr, OEM approved reference: 1.500 hr

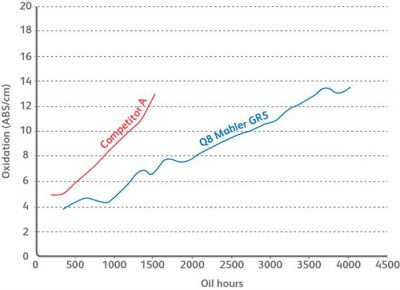

Over 4.000 hr drain interval with Q8 Mahler GR5* – Oxidation value

*Performance of competitor at equivalent conditions. Same engine, same operating conditions, same gas.

**OEM maintenance schedule: 2.000 hr, OEM approved reference: 1.500 hr

Notes

- Customer confirmed to be “very happy” with the performance of Q8 Mahler GR5, but was forced to switch to Competitor A after the trial period (>10.000 hr) because of existing maintenance contracts.

- Due to this product switch, a back-to-back performance comparison between Q8 Mahler GR5 and Competitor A under equivalent conditions was possible.

Observations

- With Q8 Mahler GR5 the customer achieved 4,000 hour oil life without a filter change during the period. The engine condition after 10,000 hours was excellent.

- With Competitor A the customer achieved 1,500 hours oil life with a filter change every 500 hours. The condition of the engine was unknown.

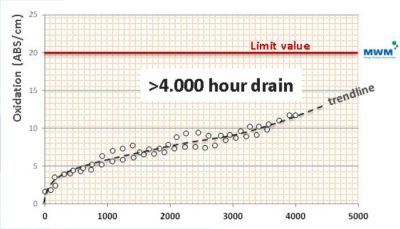

Case Study 2: Caterpillar / MWM Duitsland – Prestaties bij langer olieverversingsinterval – (Q8 Mahler GR5 met biogas)

Observations

- OEM approved competitor’s product was drained at 2,000 hours.

- Excellent result for Q8 Mahler GR5, with extended drain of greater than 4,000 hours.