At the end of the 19th Century, those who operated stationary gas engines would have used a base lube oil without any performance or engine protection additives to lubricate their running machine. The lubricant was delivered to the moving parts by pump, drip feed, and a mechanic with a long-spouted oil can. It’s not known how frequently they had to change the oil or replace mechanical parts; but today, both those factors are of great importance for the power generation industry where both availability at short notice, and duration of operation are critical requirements.

So how does Q8Oils focus its research and development to achieve:

Cleaner engines

Longer oil drain periods

Lower total operational costs (TOC)

Product development is finding the perfect balance for a specific application, including resolving a conflict between oil solubility and the amount of sulphated ash. Solvency is related to the level of insoluble substances the oil can hold before precipitation occurs. Sulphated Ash, of which detergent is one of the largest contributors, is a residue left behind after lubricant combustion. Previously, more ash has been recognised as forming more deposits, resulting in dirty engines and higher maintenance costs. Through its current level of research, Q8Oils has shown that this is not true; that the dichotomy between the demands of OEMs for clean engines, and those of the end-user for longer for extended oil drain periods can be resolved to the advantage of both parties.

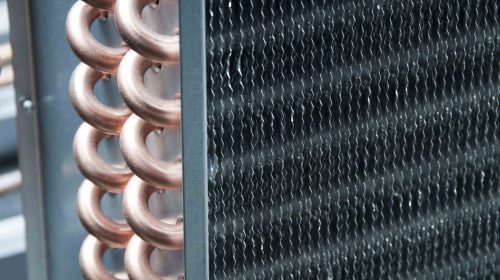

With a lube oil base selected, the Q8 Research and Development Departments, employing over 40 scientists and support staff in Italy and the Netherlands, takes over. The development team employs a technique known as additive chemistry, and by adding controlled weights of chemical elements, seeks to achieve the features required to improve the operation of the engine.

Oxidation and nitration control

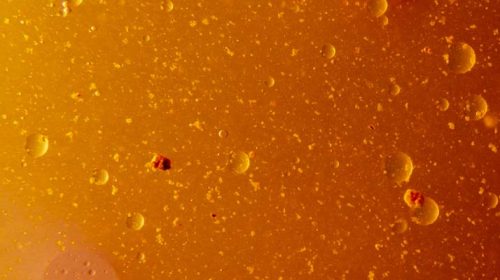

High pressure and high temperatures in the presence of oxygen and nitrogen produce an increase in oil viscosity and weak organic acids. Successful oxidation control extends oil life and keeps the pistons clean, reduces liner and piston lacquering, and prevents ring groove deposits. Preventing nitration retards the reaction of the oil with nitrous oxide (NOx) that is a result of combustion, and limits the growth of sludge, rust and corrosion.

Q8 Mahler’s successful oxidation control extends oil life and keeps the pistons clean, reduces liner and piston lacquering, and prevents ring groove deposits.

Solubility

Detergent and dispersant additives keep the metal surfaces of the engine free from the formation of deposits, neutralising the acids created during the combustion process.

During the ageing process of the oil, oxidation or contamination will form insoluble sludge, varnish and resin that adhere to surfaces. This can block lubrication channels and cause damage to the engine’s internal components.

Deposit control

Q8’s Mahler products utilise metallic additives to improve oil performance, preventing frictional wear, and maintaining the Total Base Number. These additives burn in the combustion chamber forming an ash, some of which prevents the molecular welding of hot metal surfaces that are in contact, thereby protecting against valve seat recession.

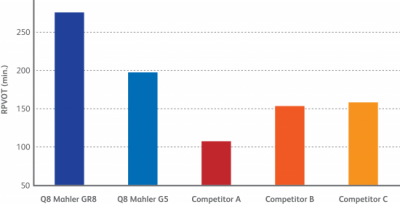

The problem with deposit formation is that too much of it will lead to pre-ignition, which reduces engine efficiency and productivity. Q8Oils subsequently developed a test to demonstrate an oil’s tendency to leave harmful deposits in the combustion chamber, and the point at which pre-ignition is initiated.