Exposure to mists from metalworking fluids forms a potential risk to machine operators. The best way to avoid health problems is installing a risk and fluid management program and selecting safe and healthy products.

Inhalation of the mist generated by neat & soluble metalworking fluids can lead to respiratory diseases such as COPD (chronic obstructive pulmonary disease) and EAA (extrinsic allergic alveolitis), also known as hypersensitivity pneumonitis.

Employers must ensure that adequate measures are taken to reduce the level of operator exposure to mist.

How mist is formed

Metalworking fluids are a complex blend of carefully selected chemicals designed to provide numerous functions in the metal manufacturing process. The ingredients and composition of metalworking fluids can vary significantly.

All fluids have a certain tendency to form aerosols or mists. This tendency is dependent on the type & condition of the fluid and the surrounding environment.

Misting is the formation of liquid particles suspended in the air.

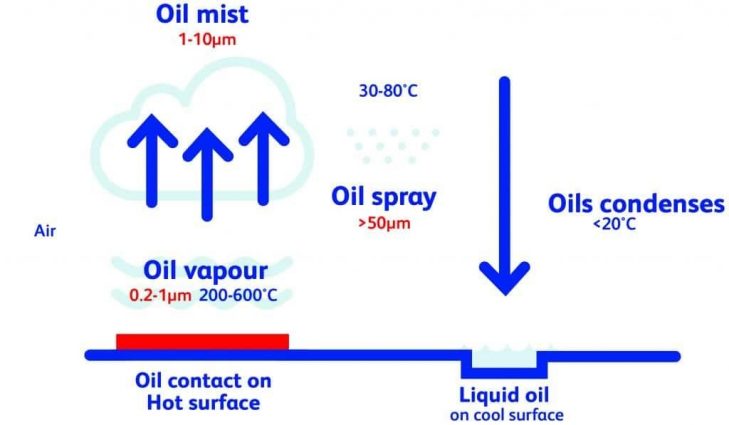

Oil mist may form when oil is sprayed with high pressure or when oil connects with a high temperature surface & vaporizes. When this comes in contact with comparatively lower air temperature it condenses. This happens while the fluids interact with the moving parts during machining.

The risks of metalworking fluid mist

The inhalation of mist is strongly associated with cancer and occupational asthma. There is also a risk of lung disease and breathing problems as chemicals and micro-organisms irritate the lungs. This can be exasperated by those who already suffer from asthma. Conditions can vary from mild to extreme & debilitating subsequently affecting both the quality of life and ability to work.

The risk of exposure is more acute within indoor environments where conditions favour the generation & collection of mist particles.

Excessive or long term exposure to metalworking fluid mist can result in various long term health conditions:

- Nasal & ocular irritancy

- Occupational extrinsic allergic alveolitis (EAA)

- Occupational asthma

Risk control is difficult

Employers are responsible for controlling exposure to hazardous substances & suppliers are responsible to report these substances, however the hazards associated with mists can be less obvious and not immediate.

The question is: what can you do to minimize the health risks for operators exposed to metalworking fluid mist? It is possible to select a less hazardous fluid in its supplied state. However there is no such thing as a healthy mist!

A metalworking fluid is usually used in an open system susceptible to contamination over a long period of time. This can be both chemical such as tramp oil and biological such as bacteria and the subsequent endotoxins from live & deceased bacterial cells. This raises the question: if you can’t 100% control what is in the fluid how you can control what goes into the mist?

How to minimize exposure risks?

One way to minimize the exposure risks of metalworking fluid mist is by installing an effective risk management program. For this we can adapt the HSE’s APC approach used for risk assessments:

1. Avoid

- Replace the fluid by a less harmful product.

- Introduce controls such as equipment and tools.

- Reduce prolonged exposure by installing a certain working methodology.

2. Protect

- Ensure the correct PPE (Personal Protection Equipment) is available and used.

- Install an adequate local exhaust ventilation (LEV) system to extract fumes and mists.

- Provide adequate training & education.

3. Check

- Monitor and record the good working of the LEV.

- Install a fluid management system

- Report and record operator health complaints

Fluid condition monitoring

It is strongly recommended to carry out a fluid condition monitoring program and to preserve the records for a minimum of 5 years.

Q8Oils recommends a balanced fluid condition monitoring plan with both short and long term analysis:

Daily/critical analysis

- Appearance & odour

- Surface oil, creaming & water layers

- Concentration by refractometer

Weekly-bi weekly

- Temperature

- Record pH

- Bacteria & fungi

Monthly/less critical

- Water hardness

- Conductivity

- Foaming

- Filters

When using metalworking fluids it is crucial that the concentration and operating conditions are within the recommended limits.

Choosing the right product

Another way to minimize the risk of metalworking fluid misting is selecting the best product that combines health & safety with performance & economy.

It is also important to consider the product in use throughout the full machining cycle. For instance a product which is more expensive and hazardous may in fact be a safer long term option by protecting the fluid and thus operator from exposure to harmful micro-organisms.

Q8Oils offer a full range of neat & soluble metalworking fluids designed to provide the optimum balance of safety, productivity and economy over the full life of the fluid in use.