How can you objectively compare the performance of different oil types and brands? It is a question that many gas engine owners have wondered about. Q8Oils’ performance evaluation test is the answer. It gives our customers a perfect comparative view on oil consumption, engine downtime, production efficiency and the overall value for installation owners.

Comparing oil performances at the ENGIE site in Grigny

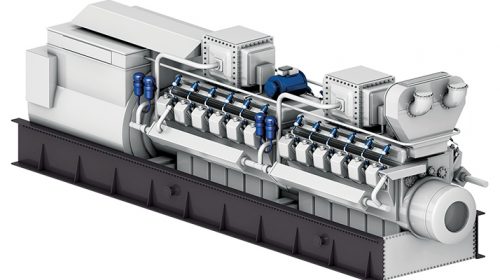

Earlier this year Q8Oils performed a performance evaluation test at the production facilities of ENGIE Réseaux in Grigny (France). In this test we compared the performance of the Q8 Mahler GR5 synthetic based gas engine oil with the previously used A-brand competitor oil on two INNIO Jenbacher 616 (F) engines.

Clarke Energy, distributor of INNIO Jenbacher engines and a company with a high credibility, performed the endoscopic control and issued the test reports of both engines.

Summary of test reports

Engine GE1 with Q8 Mahler GR5

- first oil drain after 2.300 hours without change of filter.

- Oil consumption: 0.055 gr/kwh

- Number of oil drains per year : 2 (including 1 oil drain at season start-up)

Engine GE2 with Q8 Mahler GR5

- first oil drain after 2.300 hours without change of filter.

- Oil consumption: 0,054 gr/kWh

- Number of oil drains per year : 2 (including 1 oil drain at season start-up)

A-brand competitor

- Oil consumption: 0,150 gr/kWh

- Oil drain interval: 1.300 to 1.700 hours

- Number of oil drains per year : 3 (including 1 oil drain at season start-up)

Customer benefits calculation

By combining the oil costs and exploitation costs, the customer benefits were calculated:

- Maintenance cost reduction per engine using the Q8 Mahler GR5: 5.300 euro per year

- Total gain for the ENGIE site in Grigny: 10.600 euro per year

Next to the financial benefits, the Q8 Mahler range offers specific benefits:

- Clean engine parts

- Low deposit tendency

- Extended oil drain intervals

- Excellent anti-wear properties

- Increased operation efficiency

Q8Oils’ performance evaluation test convinces ENGIE

The performance evaluation test at the Grigny site convinced several Managers at ENGIE to use Q8 Mahler GR5 for their engines for the next cogeneration season. Next to ENGIE, many other customers have experienced the benefits of extended oil drain intervals and the low deposit tendency of the Q8 Mahler range.